First, the manufacturer will purchase thin glass from the supplier of glass for cutting. (The size of large glass is: 1100*900, 480*380, etc.); the thickness of glass currently has the following thicknesses (unit: MM). 0.4MM, 0.33MM, 0.20MM, 0.15MM and so on. According to recent market observations, 0.33mm thickness tempered glass is more popular in the market.

2.CNC machining

The rectangular small-sized glass processed by the first cutting process is processed by the CNC engraving and milling machine according to the shape and size of different mobile phone models, and processed into a cell phone glass screen protector with accurated hole.

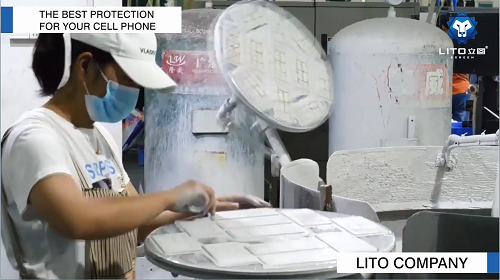

3.Polishing or flat grinding

After CNC machining, due to the operation during processing or other reasons, as well as the market demand for the curvature of the edge of the tempered glass screen protector, it is necessary to carry out the processing of polishing process, which can effectively remove the scratches on the surface of the glass protector and increasing the curvature and brightness of the edges of the glass protector to achieve a beautiful and durable function.

4.Ultrasonic cleaning

After the sweeping of the tempered glass screen film, it is necessary to clean the pulverized powder, and divide it into 5 different levels of cleaning tanks. After cleaning, put it into the oven for drying.

After drying, enter the quality inspection process, check the defective products (the products are directly invalidated)

5.Tempering Glass to make its stronger

The principle of tempering: the glass product is treated in a KNO3 melt at about 400 °C for several hours to exchange K+ and Na+ to form a compressive stress layer on the surface of the glass. When the glass product is subjected to an external force, the external force is suppressed and the expansion of the micro crack is suppressed. To improve the mechanical strength, the normal glass screen protector needs to be tempered in a 400-degree potassium nitrate tempering furnace for about 4 hours, so as to ensure the surface hardness and explosion-proof of the glass.

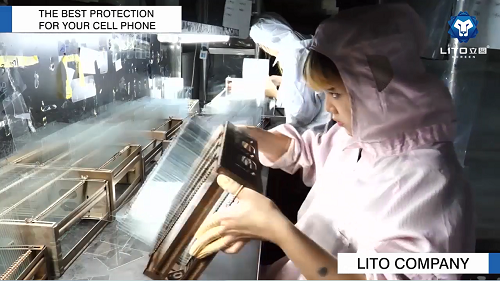

6.Ultrasonic pure water cleaning

This process is related to the cleanliness of the finished product,if the water is not pure as request or didn't clean well at this step then the glass screen protectors will have dots or dust inside of the glass.

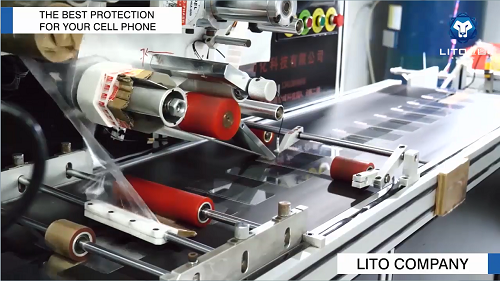

7.AB Glue

To make the AB glue and glass paste together ,all of this steps have to be made in the dust-free workshop and every worker have to wear the dust-free cloth ;before going inside there is one door with the machine that will remove the all dust for the people.

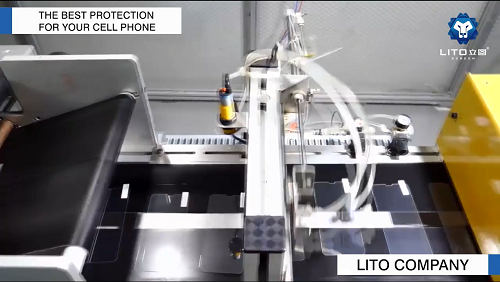

8.Oil-Coating

In order to prevent the tempered glass screen guard from being contaminated, the tempered glass protective film produced in the industry is now oiled. Generally, the anti-fingerprint oil is applied to achieve the effect of preventing oil stains. The oiling process is now available in three ways: A: hand coating, B: spraying, C: plating. The processing effect is increasing in turn. Of course, the related processing costs will increase.

9.Packaging

After the quality of the products processed through the above processes, the final process - packaging.

没有评论:

发表评论